A Professional and quick service

An extremely wide portfolio of Standard Components and Specific Technologies

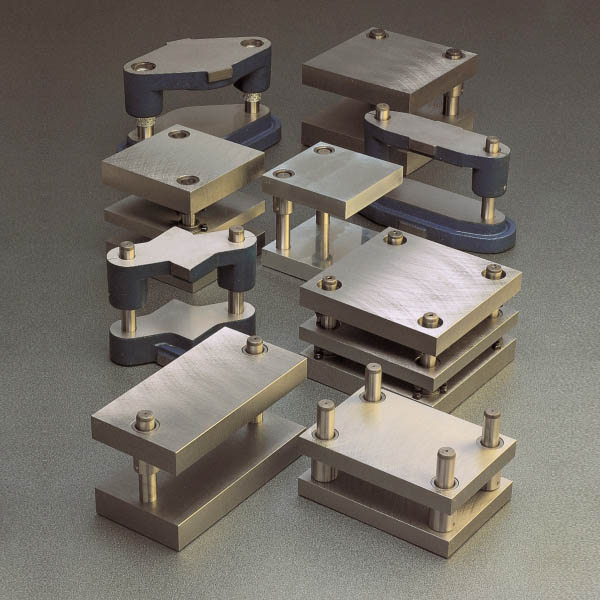

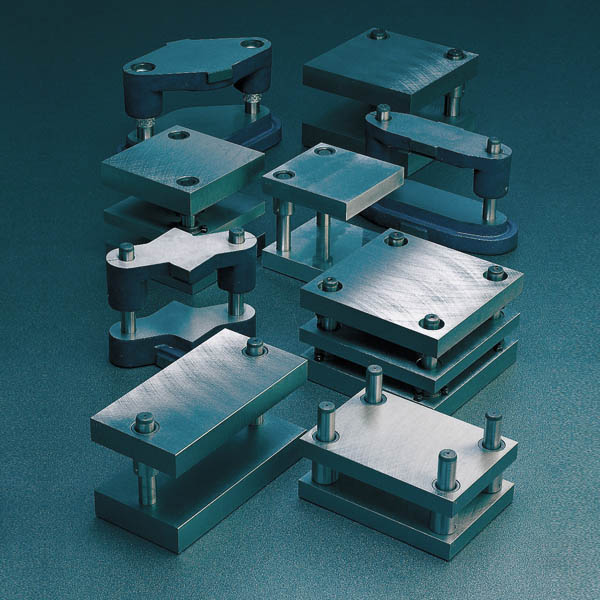

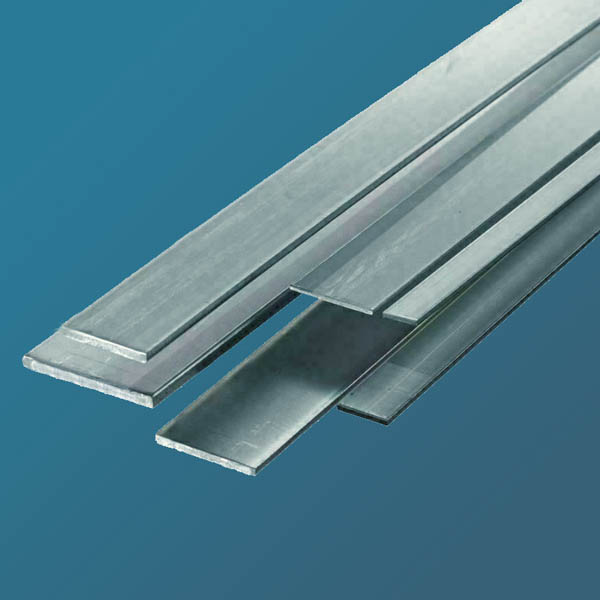

Metal Stamping

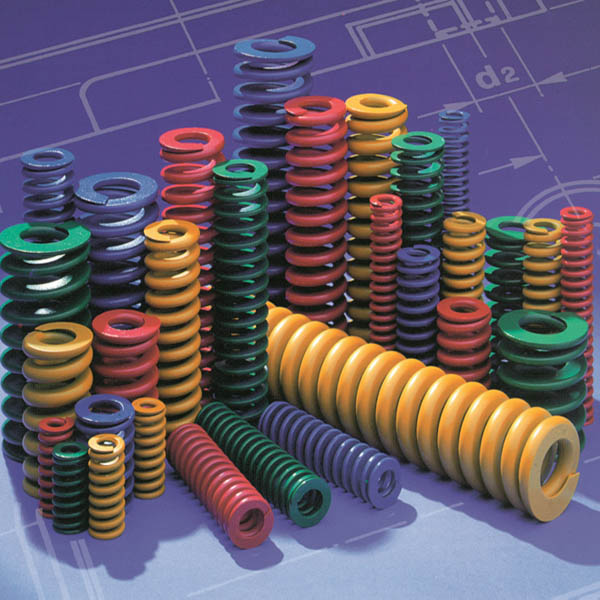

Standard Components for tools and dies

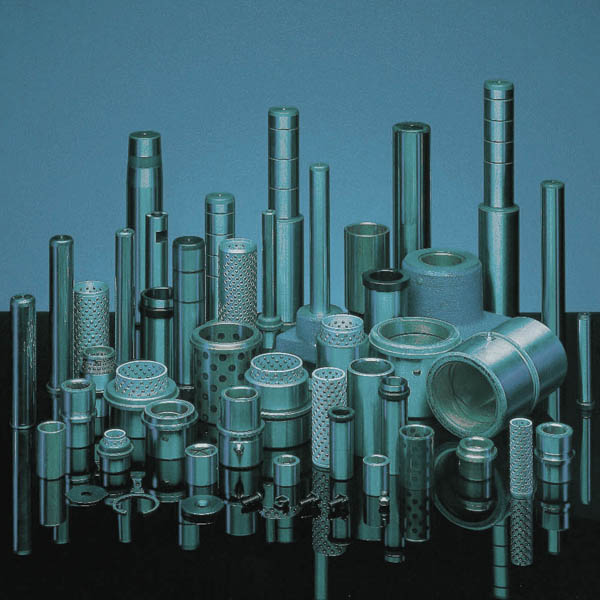

Injection Moulding

Standard Components for Plastic Injection Moulds

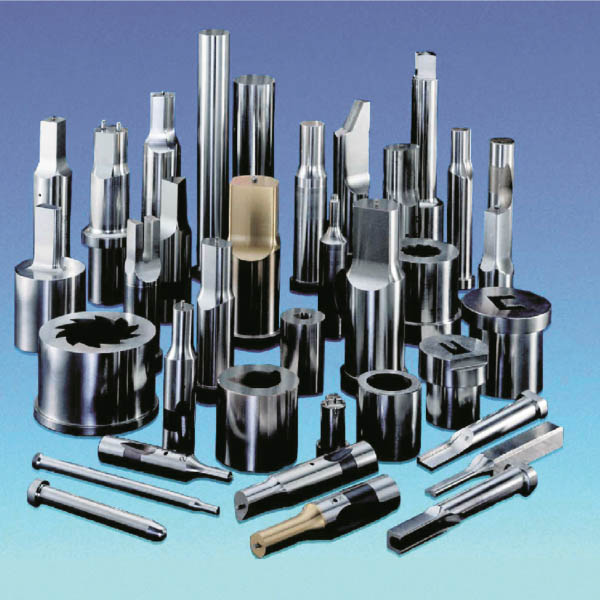

Custom Machining and Technologies

A wide range of Custom Machining and Innovative Technologies to satisfy all our customers needs